Used Excavator Bucket Buying Guide

All of the digging, trenching, scooping, and scraping done in an excavator is only possible because of the excavator bucket attached at the end of the excavator’s arm. And since every action will add a little more wear to the bucket, the life of an excavator bucket is always finite.

If your bucket is nearing the end of its usefulness and you’re in search of a used excavator bucket to replace it, you might be wondering what exactly to watch for in your search. To help you search and ensure you find the perfect replacement excavator bucket, we’ve put together this short and simple excavator bucket buying guide.

Used Excavator Bucket vs New Aftermarket Excavator Bucket

If you’re in the market for a replacement excavator bucket you’ll quickly find you have options both for new aftermarket buckets and used excavator buckets. If cost is a factor, the advantages of a used bucket are clear and, because buckets are sold for a variety of reasons from a change in the design an operator needs to a good used bucket outlasting a machine, there are often a wide range of used buckets available. As long as you know what to search for and how to evaluate the bucket, often a great used bucket solution is out there.

To ensure the bucket you find is the one you need, here are 4 simple considerations to watch for in your search.

How to Determine If the Excavator Bucket Will Fit Your Excavator

Your excavator is designed to work with a range of excavator bucket sizes and weights, but every excavator has an upper limit and at a certain weight the bucket will bog down your machine. If you’re buying a similar bucket to what you have now, you’re generally ok, but be watchful of big jumps in size and weight.

Ensuring the bucket will actually fit and mount to your excavator can be done in two ways: searching by make, model, and serial number or searching by bucket dimensions.

Finding the make, model, and serial number of your excavator is as simple as taking a close look at your machine and matching those specs to a bucket that came off the same machine. With those details, you’ll be able to search a reputable reseller's database or contact an excavator bucket seller.

However, since many buckets often fit more than one machine, if you only search by buckets labeled for a certain machine, you’ll often limit your search. With a few simple measurements, you can often open up a much wider range of available buckets.

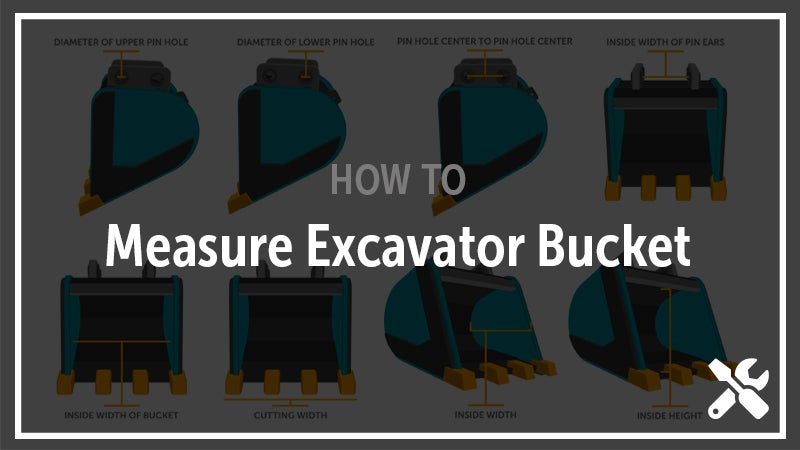

To search, you’ll need the size of your pinholes, distance between pinholes, inside width of pin ears, and a few other measurements. To make your search that much easier, we’ve actually put together a simple measuring sheet and a short explainer. Grab the measuring guide (below) and read that post to make your search simple.

Print Our Bucket Measuring Guide »

Check the Condition of the Excavator Bucket

Whether you’re searching online or on foot, you’ll want to take a good look at the condition of the bucket -- a reputable and organized seller will always provide pictures. While some rust is often common, make sure rust hasn’t affected the structure of the bucket. If the rust is minor, but you still want the bucket to look new and to be better prepared to avoid more rust in the future, you can plan to paint the bucket yourself or ask the seller about reconditioning the bucket themselves to save time.

You’ll also want to look for cracks and holes in the bucket. If you’re handy with repairs you can often touch up a bucket yourself, or again ask the seller about reconditioning the bucket. Either way, you should have a clear picture of the condition of how the bucket will arrive before you buy it.

Check the Excavator Bucket Teeth

When you inspect the bucket or its pictures, you’ll want to take a close look at the teeth -- both to ensure they are suitable for your needs and to take into account their condition. Since teeth and the edge of the bucket can vary in design, you’ll want a bucket that is suitable for your most common jobs (or plan to change the teeth to suit).

In used buckets, you’ll often find a wide range of teeth conditions. Take a look at the teeth and determine if they’re not overworn for your work or if you need to plan to replace them yourself or have them replaced in the near future.

Determine the Excavator Bucket Design

Since excavators interact with a wide range of materials and perform a diverse set of jobs, the design of an excavator’s bucket can vary significantly. In your search, you’ll find general purpose buckets, heavy duty buckets, trenching buckets, and grading buckets. To determine what type is best for you, evaluate the design against your most typical jobs. Remember, though reinforced sides and guards add strength and repel wear, they also add weight, and, in turn, affect the functionality and efficiency of your excavator.

You’ll also want to determine the capacity of the bucket and match that to the capacity of the trucks it will be filling and the density of the materials it’ll be handling.

With a few quick measurements and a good understanding of what to look for in your excavator bucket search, you should be searching (and hopefully finding) the perfect replacement bucket for your excavator, simply and quickly.

If you still find searching difficult, feel free to contact our Parts Specialists -- they can search our deep inventory, as well as, our national parts network. And as a leader in salvaging excavators, we understand what to look for and how best to evaluate our buckets and ensure they’re up to the job for our customers -- just give us a call.