Simple Articulated Truck Maintenance

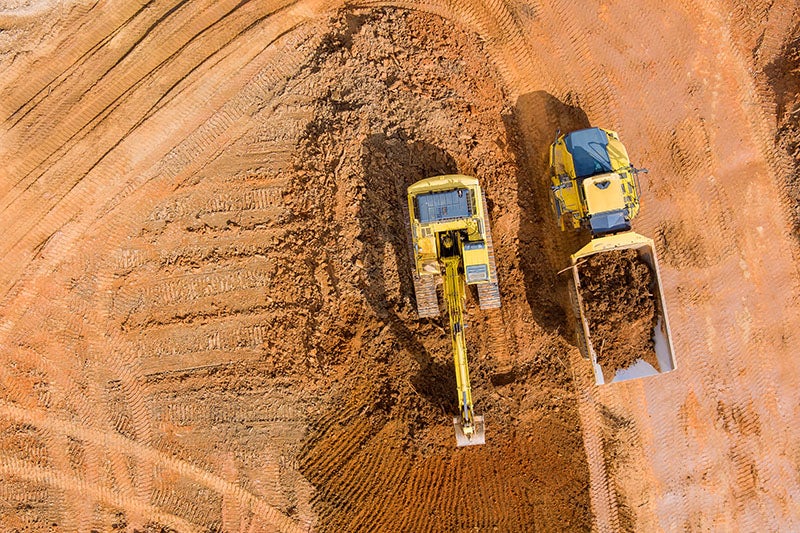

With frequent trips, longer and faster travels than other machines, and challenging terrains, the work of an articulated truck can put the machine under intense and constant pressure. Luckily, the smart designs of an articulated truck at the hands of an expert operator are often up to the job. Still, the unique design of the machine means that specific care should be taken to extend the life of the parts on the machine and the machine overall. To help, we’ve put together these short tips to help you keep your truck going.

Plan Routes and Paths with Loads in Mind

Often the jobsite and the location of materials will dictate the route an articulated truck takes as it moves materials about a worksite, but sometimes with a closer look you’ll find that paths can be changed, the direction of flow can be altered, and obstacles can be avoided.

Even though an articulated truck brings with it better mobility than other haulers, smart planning for routes can help you decrease wear on the machine. When you decide how an articulated truck will flow around the worksite, look to minimize sharp turns or heavy inclines, especially in directions where the truck will be fully loaded.

Watch Your Tires and Rims

On a large, fully-loaded articulated truck there’s a lot riding on the wheels, and low pressure, cuts in the tire, heavy damage to rims, and loose or missing nuts can instantly jump from a small problem to a critical, machine-ending catastrophe. Throughout the day, an articulated truck operator should periodically check the condition of the tires (both when the machine is unloaded and loaded) and the overall undercarriage. Not every tire issue will be simple and easy to spot, but spotting the ones that are visible can save in repairs and downtime in the long run.

Learn What to Search and Inspect in Used Tires

Stick to Engine and Hydraulic Oil Change Schedules and Watch for Leaks

The operator’s manual for your articulated truck will have defined periods for changing engine and hydraulic oil, and keeping to that schedule is a proven way of extending the life of your engine and hydraulic parts. In addition, you should routinely check the oil, both for levels and to spot any contamination.

A dusty or dirty environment (common to many articulated truck worksites) can lead to debris build-up and conceal oil leaks so keeping a truck as clean as possible and focusing attention when inspecting areas where leaks commonly form is a proactive approach to finding and fixing developing issues.

Keep it Greased

No machine operator wants to spend a day with their grease gun in their hand when they could be behind the wheel of their machine, but a lack of proper lubrication is commonly cited as a reason why a part wore out faster than expected. Even though an articulated truck is designed to work in the toughest conditions, the unique designs and movements of the machine always require a well-lubricated environment and even the shortest span under less than ideal grease conditions can lead to deep issues quickly.

Restrict Movement When a Load Is Not Secure

The worksite an articulated truck calls home is often a fast-paced stream of machines keeping to tight schedules and maximizing their daily trips. For some operators, this can lead to a machine getting a jumpstart before a load is fully settled or a dump box has come to a full rest. This early movement can apply intense pressure to connection points and cylinders and, over time, introduce bends or breaks into sensitive parts.

During and after unloading, lifting or lowering the box while the machine is moving can be a requirement of a specific task, but minimizing those times and reducing the aggressiveness of those combined actions can reduce the pressure applied to the machine and its parts.

Keep the Machine and Cab Clean

Unless your articulated truck is hard at work in a dish soap mine, it’s going to collect dirt, mud, and other debris during the course of its day, and spending hours keeping it clean can seem like a poor use of time. However, heavy dirt and debris are more than cosmetic issues as they can add to strain on the machine and make finding and repairing developing issues more difficult — which will turn a fast fix into a long downtime.

A dirty construction equipment cab is an often overlooked issue, as well, but ensuring a cab is free of junk and windows are clean and unobstructed can increase visibility, operator comfort, and even ensure proper safety for the operator.

Ensure Both Operators Are Well-Trained

An articulated truck never works alone, and even the best truck driver can be impacted by an inexperienced operator behind the controls of whatever is loading the truck. A well-trained and knowledgeable team can often work together in a fast-moving and steady stream of collaboration while a struggling team can apply undue force to the truck from improper loading or even damage to equipment from collisions.

Give Your Machine A Frequent Walkaround

You’ve already read all the reports that too much time on your seat is hard on your health so encouraging frequent inspections is a way of combining better health practices for an operator and an articulated truck. Of course, there’s times and worksites where it's better to keep an operator in a cab as much as possible, but if there are periods throughout the day where a short visual inspection of the machine can be performed, encouraging the process is often a way of finding troubles just as they’re starting.

Most of us could probably do a little better with our maintenance, but committing to a solid and smart maintenance plan is often a simple step to making sure the number of trips an articulated truck will take before retirement is at a max and that each one is as productive as possible.

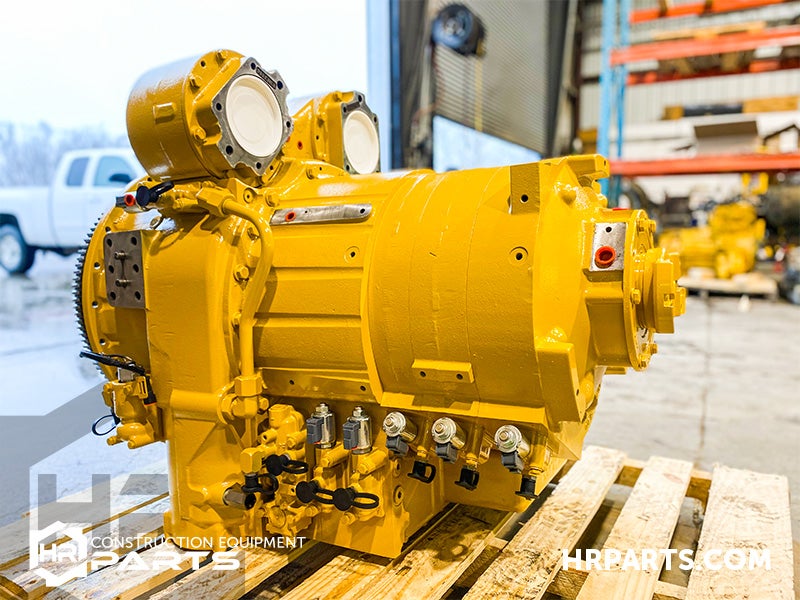

As a leader in salvaging construction equipment, we take pride in helping our customers keep their machines going and their worksites running. If you’ve found yourself in need of a replacement part for your articulated truck, our Parts Specialists are here to get you back up and running quickly. Just drop them a line.

Articulated Truck Diagram and Image Gallery