What Is a Slewing Ring with Slewing Ring Diagram

If you’ve ever sat in the cab of an excavator, grabbed a bucket of dirt, spun a circle, and sent that load sailing off to a perfectly placed pile, you probably already know that under your feet a slewing ring helped make that job possible, but since that slewing ring is buried deep in your machine and hidden from view you might wonder just how it works. Whether you’re looking to learn more about your own slewing ring or you’re just on a search for construction parts knowledge, we’ve put together this short article to take a look at this interesting and important part.

What is a Slewing Ring?

- A slewing ring bearing is a bearing that combines traditional elements of a bearing with gears and mounting holes for directly mounting the ring to structures, allowing each structure to rotate freely and independently of the other.

- In heavy construction equipment, the hybrid-like format of a slewing ring bearing allows for heavy components on a machine to turn and swing smoothly and repeatedly, even as loads are applied to the machine.

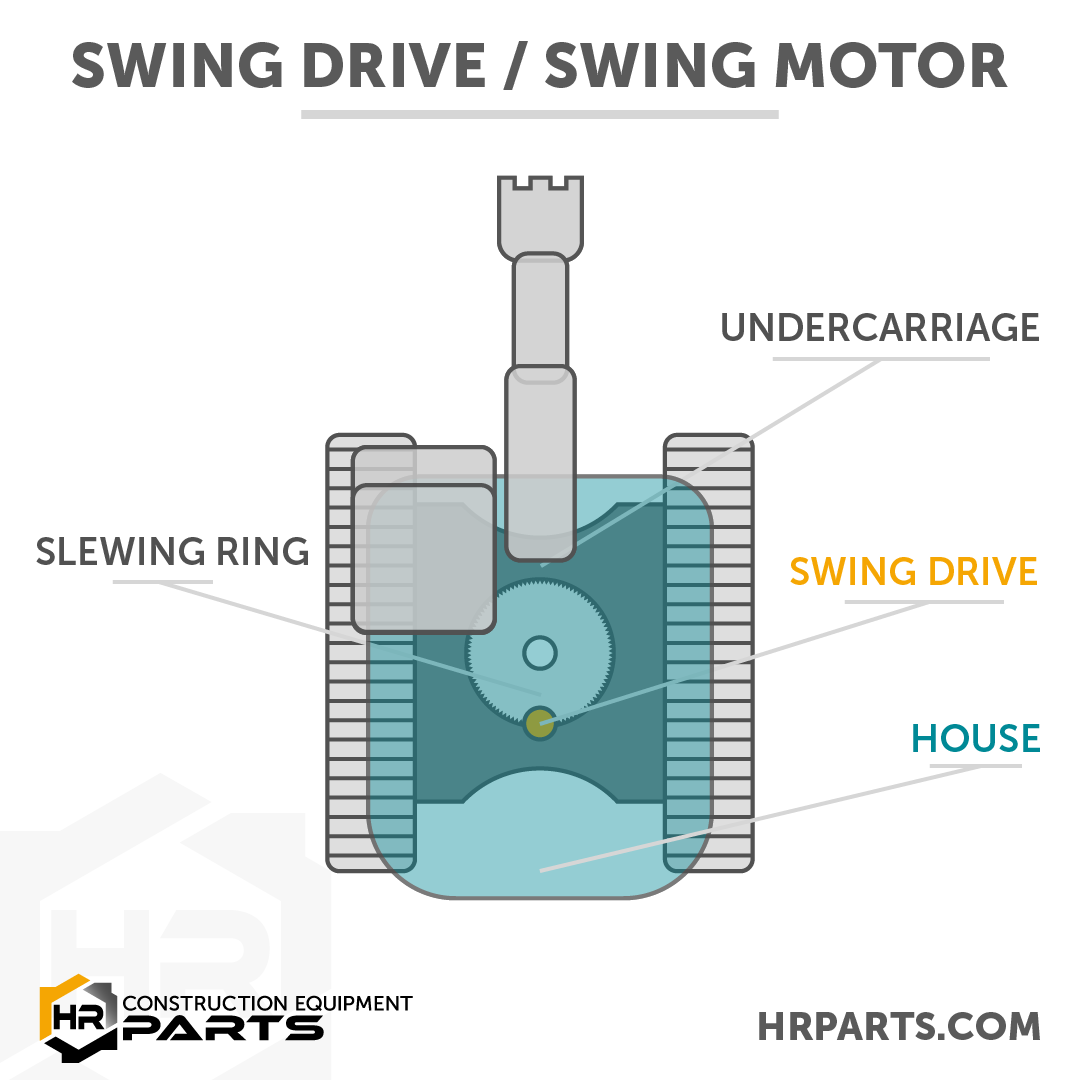

- In an excavator, a horizontally-mounted slewing ring bearing sits between the excavator’s house and the excavator’s undercarriage and its unique design allows for the excavator’s house and attachments to swing infinitely in a circle through the aid of a swing drive attached to the house.

How Does a Slewing Ring Work?

- A slewing ring works in much the same way as a traditional bearing by utilizing bearing races and either ball or roller style bearings and friction-reduction elements to allow efficient movement around a center axis.

- A slewing ring bearing consists of an outer ring and an inner ring with a gear integrated into one of the rings (either on the inner side of the inner ring or the outer side of the outer ring). Gears on a drive mounted to a structure interact with the gears in the slewing ring and facilitate rotation of the free-moving structure.

- Between the rings of the slewing ring a lubricated environment contains rolling elements and seals exist on each side of the slewing ring to ensure the environment remains lubricated and avoids contamination from debris.

- Like all bearings, the design of a slewing ring allows for movement to be transferred along a guided path as efficiently as possible.

How Large Are Slewing Rings?

- Slewing ring bearings are used across industries and machines and developed for diverse purposes, resulting in a wide range of sizes and designs. In heavy construction equipment, a slewing ring will range in size based on the machine and its purpose.

- In excavators used in heavy construction applications, the size of the slewing ring will be proportional to the size of the machine. An excavator slewing ring can range from a few feet wide on a mini excavator to behemoth slewing rings measuring over 20 feet on excavators used in mining operations and even bigger.

How Are Slewing Ring Bearings Made and Checked?

- Like all bearings, slewing rings must be designed and built to stand up to repeated movement, consistent friction and wear, and high temperatures due to friction and long-term, uninterrupted use.

- In an excavator, even though the slewing ring might be very large, it must still be built to operate under precise and specific specifications. A poorly manufactured slewing ring bearing or heavily-worn slewing ring will lead to inefficiencies in movement and even cascading adverse effects on a machine.

- Since a slewing ring is mounted directly to upper and lower structures the mounting positions need to be flat and exact. Mechanics and operators consistently test the input needed to perform actions (as this indicates issues inside of the slewing ring) and measure the tolerance (play) of the slewing ring using a tool to check the distances of the parts as they rotate.

What Are the Other Names for a Slewing Ring?

- Few other parts are referred to by such a diverse set of names as a slewing ring bearing. Different manufacturers, operators, and regions refer to slewing rings as turntable bearings, ring gears, swing bearings, slew gears, slew rings, and even other combinations.

- The wide range of names is likely a result of the hybrid qualities of the slewing ring -- some will identify the ring as a bearing, others as a gear, and still others as the unique way in which it is mounted and situated on the machine.

What Are the Parts of a Slewing Ring?

Gear

In a slewing ring bearing, either the inner ring or outer ring will incorporate a gear mechanism where the teeth of a drive interact with the teeth of the gear. This interaction will translate the output of the drive into motion around or inside the gear.

Mounting Holes

Mounting holes on a slewing ring will be incorporated into the inner and outer rings, allowing each ring to be fixed to a structure.

Inner Ring and Outer Ring

The inner and outer ring of the slewing ring contain the rotating parts and are connected directly to structures. In an excavator, the structures are the house and the undercarriage and, since each ring can move freely of the other, an excavator can spin clockwise and counterclockwise 360 degrees and even in repeated circles.

Rolling Elements

Inside of the slewing ring, balls or rollers act as rolling spacers to reduce the friction and allow each ring to spin smoothly and freely. The rolling elements are kept in a heavily-lubricated environment and contained in a bearing raceway created by the inner and outer ring. In large slewing rings, multiple raceways are often employed.

Swing Drive

While not a part of the slewing ring, on an excavator the swing drive is the mechanical component that interacts with the slewing ring and facilitates movement.

Learn more about swing drives in our What is a Swing Drive article.

Lubrication Element

The inside of a slewing ring is heavily lubricated to allow for less friction in movement and reduce wear between parts. A leading cause of slewing ring failure is a lack of proper lubrication and in heavy construction equipment the monitoring and continued lubrication of a slewing ring is a routine and important task.

Seals

Seals on the upper and lower halves of a slewing ring seal the gap between the inner and outer rings. These seals are designed to maintain proper lubrication inside of the slewing ring and to ward off contamination from dirt or debris entering the slewing ring. Contamination from debris leads to increases in friction, poor operating conditions, and other problems.

Whether you call them slewing rings, slewing gears, or turntable bearings, hopefully now you have a better understanding of this part and the important role it plays in construction equipment. Thanks for taking the time to read and learn more

And as always, if you're in search of a replacement slewing ring for your excavator, our Parts Specialists are here to help. Our H&R brand slewing rings are known for their reliability and quality and our used slewing rings always leave our Recon and Rebuild shop designed to perform, day after day.

Slewing Ring Image Gallery