What is a Hydraulic Cylinder with Hydraulic Cylinder Diagram

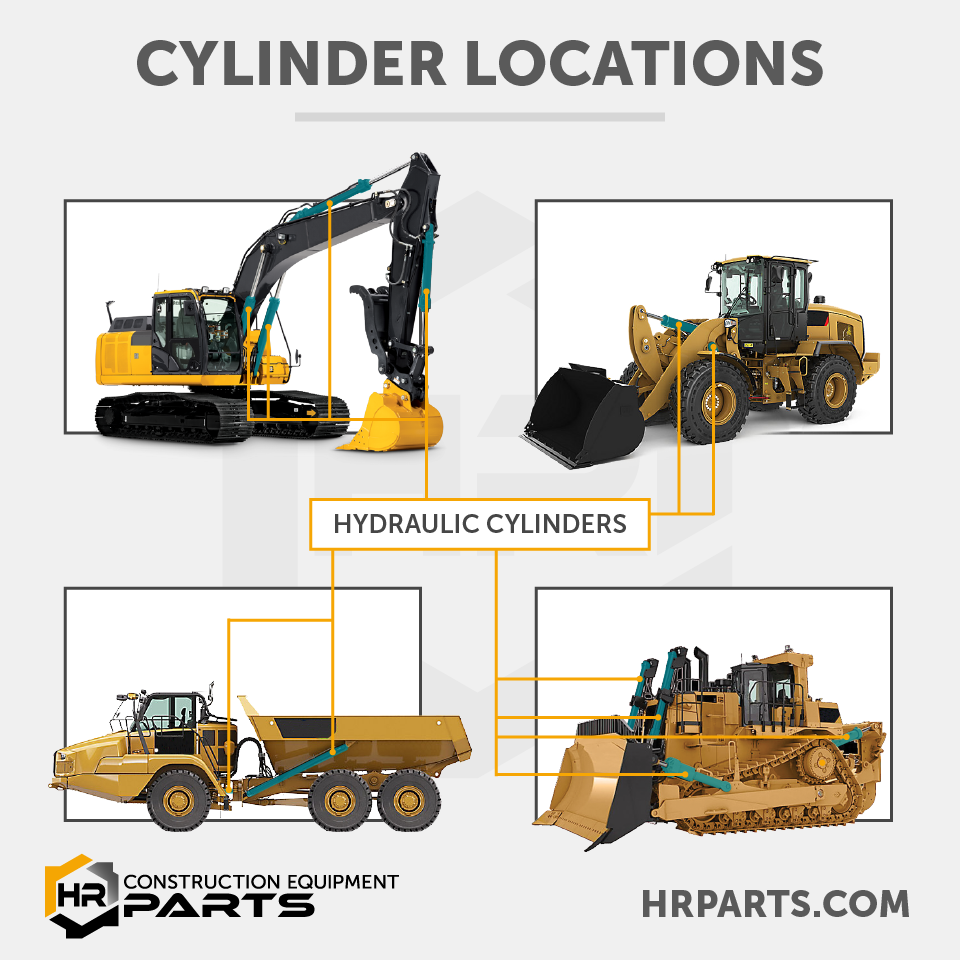

When it comes to hydraulic cylinders, at H&R we’re pretty much obsessed. Take a walk through our warehouse and you’ll find a bevy of reconditioned boom cylinders, bucket cylinders, lift cylinders, and steering cylinders. Every day, you can catch our teardown team salvaging stick, tilt, and suspension cylinders. In heavy construction equipment, cylinders are everywhere so it makes sense they’re everywhere here, but you might wonder, “Exactly why are cylinders so important in heavy construction machines?”

Whether you’re trying to get a better grasp on your cylinder know-how or you’re searching out cylinder solutions for your own machine, this one’s for you. Read on for our brief overview of what a hydraulic cylinder is and how a hydraulic cylinder works.

What is a hydraulic cylinder?

- Hydraulic cylinders are a common part in a variety of machines from excavators to bulldozers to cranes, trucks, and more. While the engine, the transmission, and the tires and tracks are designed to move the machine itself, the hydraulic cylinders are designed to move their individual parts. When a boom extends, a blade lifts, or a bucket tilts that motion was likely controlled by a hydraulic cylinder.

- At their most basic, hydraulic cylinders convert pressure into movement and for the most part they’re designed to do one of two things -- push or pull. If you look around a heavy construction equipment machine, you’ll find cylinders positioned all over it. If a component needs to extend or contract, it’s a good bet there’s a cylinder making it happen.

- Cylinders are expert extenders, but when working in heavy construction equipment they also have to be hearty enough to not just lift the huge components -- they have to be able to lift the part with an extra heavy load added on top. The end result? Big machines need big cylinders.

How do hydraulic cylinders work?

- Though the mechanisms and principles of a hydraulic cylinder can be complicated (Pascal’s Law), you don’t need an advanced degree in mechanical engineering to understand how they work.

- Hydraulic cylinders are powered by hydraulic pumps and they convert pressure into movement by controlling the amount of hydraulic oil in chambers that are exerting a force in a direction. A simple diagram below helps explain the mechanics of the process -- as fluid enters a chamber more force is applied to push or pull the piston rod in or out of the cylinder and, in turn, pivot, push, or pull the component the cylinder is connected to.

- Hydraulic cylinders come in two types: single acting and double acting. In a single acting cylinder only one chamber exists in the cylinder to hold the hydraulic fluid (or to push) and the countering force is an external mechanism like gravity. In a double acting cylinder, oil pressure is applied to a piston in two directions through two separate chambers.

❱❱ How do you use a hydraulic cylinder?

- The machine’s operator controls how a cylinder extends and retracts and this movement is tied to the movement of a component. Extend the boom cylinder on an excavator and the boom rises, extend the stick cylinder on an excavator and the stick moves closer, extend the bucket cylinder and the bucket curls in, and repeat in reverse.

- An expert operator is adept at controlling the cylinders (and in turn) the components of the machine in a way that keeps them working together smoothly and efficiently and it takes skill in knowing how much pressure to apply and when from each individual cylinder.

What is hydraulic fluid?

- Energy needs a medium to carry it and in hydraulic systems that medium is the hydraulic fluid. Like the blood in your body, the movement of hydraulic fluid in a hydraulic system is central to every action. In construction equipment, the main component in most hydraulic fluid is mineral oil and its design introduces an important aspect of its effectiveness -- avoiding compaction.

- When it comes to applying force, avoiding compaction means the force you put in will be closer to the force you get out. Though there are times when increased compaction is ideal (think of your rubber mallet versus your steel sledgehammer) in heavy construction equipment force is generally the priority.

- Besides transferring energy, hydraulic fluid must act as a lubricant for parts, help to dissipate heat, and deliver contaminants to filters.

Where on a construction equipment machine are cylinders located?

- You’ll find hydraulic cylinders spread throughout a heavy equipment machine, alone and in tandem. In many spots where a component is designed to hinge around a pin and bearing you’ll find a hydraulic cylinder connected to control that movement.

What are the parts of a hydraulic cylinder?

Cylinder Barrel

The cylinder barrel is the container for all the cylinder parts, but even more so it’s what will hold all the cylinder pressure. And in heavy construction equipment that pressure can be extreme which requires the barrel to be specifically designed to operate with high internal pressure over prolonged periods of time. The internal mechanisms and parts of a cylinder are designed to operate in specific margins and, as such, the barrel also acts as a fortification from external elements and forces. Rain, dirt, and impacts -- the barrel must be designed to ward off internal and external forces.

Cylinder Cap and Cylinder Head

At the ends of the hydraulic cylinder are the cylinder cap and cylinder head. The cylinder head is attached to the piston rod and both components are designed to contain the pressure of the cylinder and to connect in a specific way to a component to facilitate movement.

Piston

The piston is the internal component of the hydraulic cylinder that travels inside the cylinder and divides the chambers.

Piston Rod

The piston rod is attached to the piston and varies in length. The rod contracts and extends in and out of the cylinder barrel and it is connected directly to the component the operator is moving.

On its path to pushing and pulling, the piston rod must leave the barrel and, subsequently, its hydraulic fluid bath. Like a turtle sticking its neck out from its shell, when the piston rod is exposed to the atmosphere it takes on new risks, in this case, from erosion, impacts, lateral force, and even the weather.

The length of the piston rod determines how far the cylinder extends, called the stroke. A piston rod needs to be manufactured to hold a load even when the rod is fully extended. Think about holding a weight against your chest as compared to holding it with your arm extended -- like we said earlier, big machines = big cylinders.

O-Rings and Seals

The seals in and on a cylinder perform a number of duties. External seals on the piston rod fit tightly around the rod to prevent contaminants from entering the cylinder and mixing with the hydraulic fluid.

Internal seals at all connections ensure all fluid remains inside the system. Internal seals around the piston allow the piston to move with reduced friction and wear while still keeping correct pressure on both sides of the piston. While fluid that is allowed to leak outside of the cylinder leads to reduced power, so too does fluid that is allowed to leak from either side of the cylinder’s chambers.

And that rounds out our short introduction to cylinders. We hope you found it interesting and maybe a little entertaining. It should be clear that at the heart of heavy construction machinery is a whole slew of cylinders, pushing and pulling away. If you want to see how dedicated we are to our reconditioned cylinders, check out the gallery below -- we think you’ll see the pride we put into our cylinder projects and, even though we said it before, you’ll get a better idea of just how big these cylinders can get. Thanks for reading.

Hydraulic Cylinder Image Gallery