How an Excavator Swivel (Rotary Distributor) Works with Excavator Swivel Diagram

One of the core aspects of an excavator is its ability to rotate the housing and arm – multiple times and in both directions. The functionality of this free-wheeling spinning allows an excavator operator to quickly and efficiently reposition the bucket, adjust the digging angle, and move materials from a pile in the front of the machine to a truck waiting behind it.

This infinite, omnidirectional twisting is one of the key factors that make an excavator such a versatile and important machine on a construction site, but, though it might seem simple enough, it takes smart design and clever mechanics to pull off this feat. From swing motors to rotate the housing to the slewing ring that allows it to smoothly spin, a lot of well-designed parts come into play to allow the machine to rotate.

And one part that often gets overlooked is the swivel. At its core it’s not the most complex, but the smart design of the swivel cleverly connects the hydraulics in the upper part of the machine to the lower while letting each move independently.

To learn how the swivel does this task and see it in motion, keep reading.

What Does the Swivel (Rotary Distributor) Do on an Excavator?

If you’re an excavator expert, this will already be clear, but for the less excavator-enlightened, we’ll take a quick minute to explain.

If you’ve ever seen an excavator in action, you already know that the machine has an upper part with the cab, engine, and boom (the house) and a lower part with the parts that move the entire machine (the undercarriage). Since many of the parts on an excavator are hydraulic, the upper hydraulic controls, pumps, and valves need to be connected to the lower motors and final drives that propel the machine. If you picture these connections all happening through simple hydraulic hoses, you’ll quickly see the problem: a fast developing cluster of twisted, tangled, and torn hoses.

The swivel solves this hydraulic conundrum by connecting upper hydraulic hoses and lower hoses in a way that allows each to pass fluid freely and unaffected by the machine’s twists.

How Does an Excavator Swivel Work?

An excavator swivel connects the lower and upper hydraulics of the machine through a center shaft and an outside housing. By using holes bored into the center shaft, the swivel directs fluid to specific channels (or inner barrels) created by the shaft and the housing. This design allows hydraulic fluid to flow from the center shaft, through the inner barrels, and in or out of a specific hole in the housing. A bearing (or multiple bearings) allows the shaft to spin freely from the housing and seals at each end of the inner barrels contain the hydraulic fluid.

Since the center shaft can move independently of the housing without impeding the flow of the hydraulic fluid, the lower and upper halves of the excavator are able to rotate in both directions and even multiple times around the center point of the swivel under the power of the hydraulic system.

What Are Common Problems in an Excavator Swivel?

Like many parts in an excavator’s hydraulic system, one of the most common problems in a swivel is hydraulic leaks. Since hydraulic fluid is used to both power and lubricate components in the hydraulic system, leaks can lead to significant problems in an excavator and range from loss of power, increased demands on hydraulic parts, and increased wear from friction on parts and the entire excavator.

Hydraulic leaks from an excavator swivel can be either internal or external. External leaks are generally the easiest to spot since hydraulic fluid will be visible at connections or external seals. Internal leaks are created when the internal seals that divide the inner barrels become worn or damaged and allow fluid to escape the inner barrels. Since escaping fluid will lead to less efficient energy transfer, internal leaks can lead to increased demands on the excavator’s final drives, pumps, and other components.

In addition to leaks, the individual parts of a swivel can degrade over time since even in a well-lubricated system some friction will always lead to wear. Bearings and seals have a finite life and on any machine they will eventually need to be replaced or repaired.

What Are Other Uses of a Swivel?

The smart design of a swivel is not exclusive to excavators and the design can be referred to as a rotary union, center joint, rotary manifold, or fluid swivel. This use of center cavities to allow for free passage of fluid or gas while also maintaining rotational independence is found in numerous applications from cranes to wind turbines.

What Are the Parts of an Excavator Swivel?

Center Shaft

At the center of the swivel is a shaft with channels that directs hydraulic fluid through the shaft and into inner barrels created by the shaft and housing.

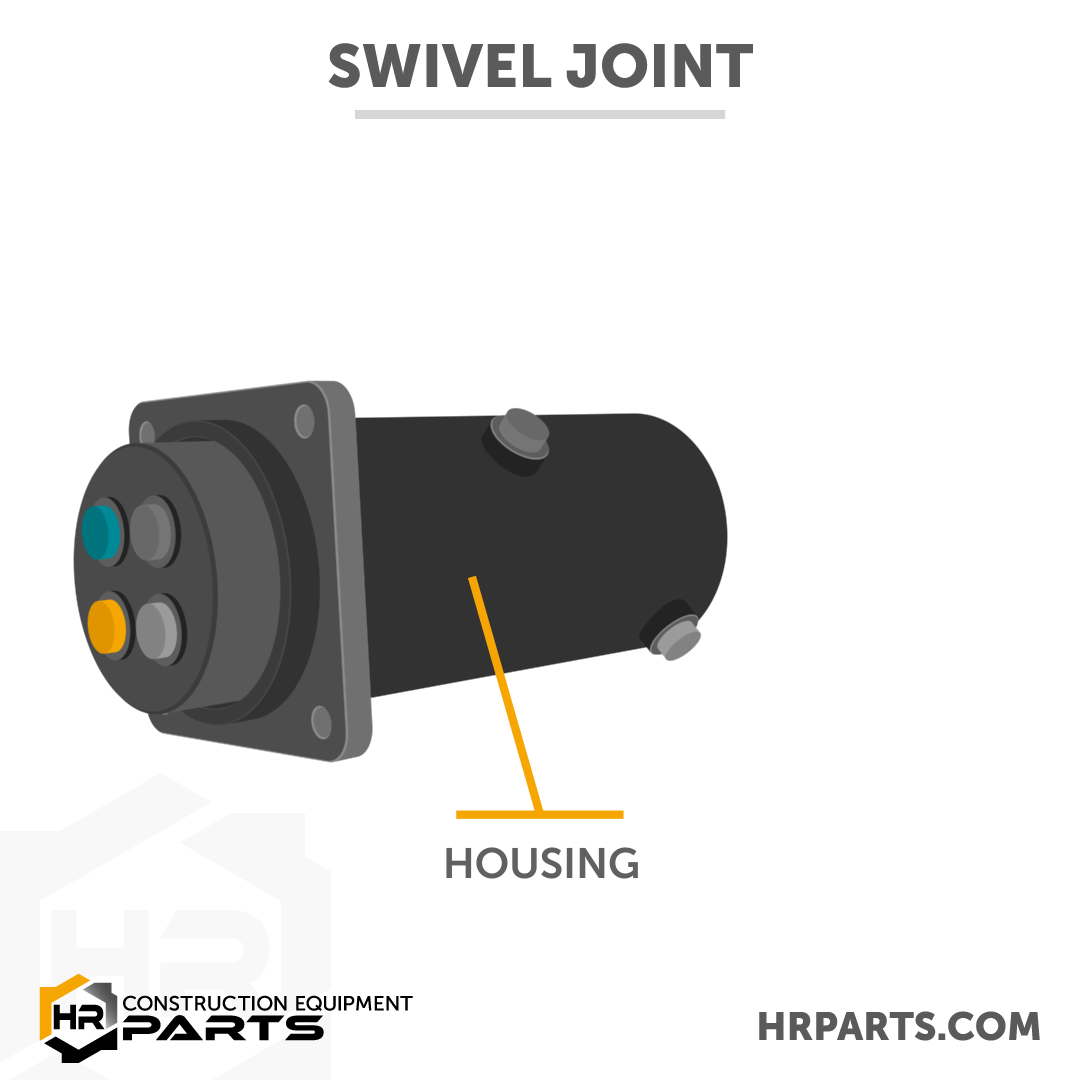

Housing [View Image]

The housing of the swivel contains the inner parts of the swivel and has hydraulic connections on its outside to connect to the machine.

Seals [View Image]

Seals are inset on each end of the cavities where hydraulic fluid flows between the center shaft and outside housing and contain the hydraulic fluid for each connected channel.

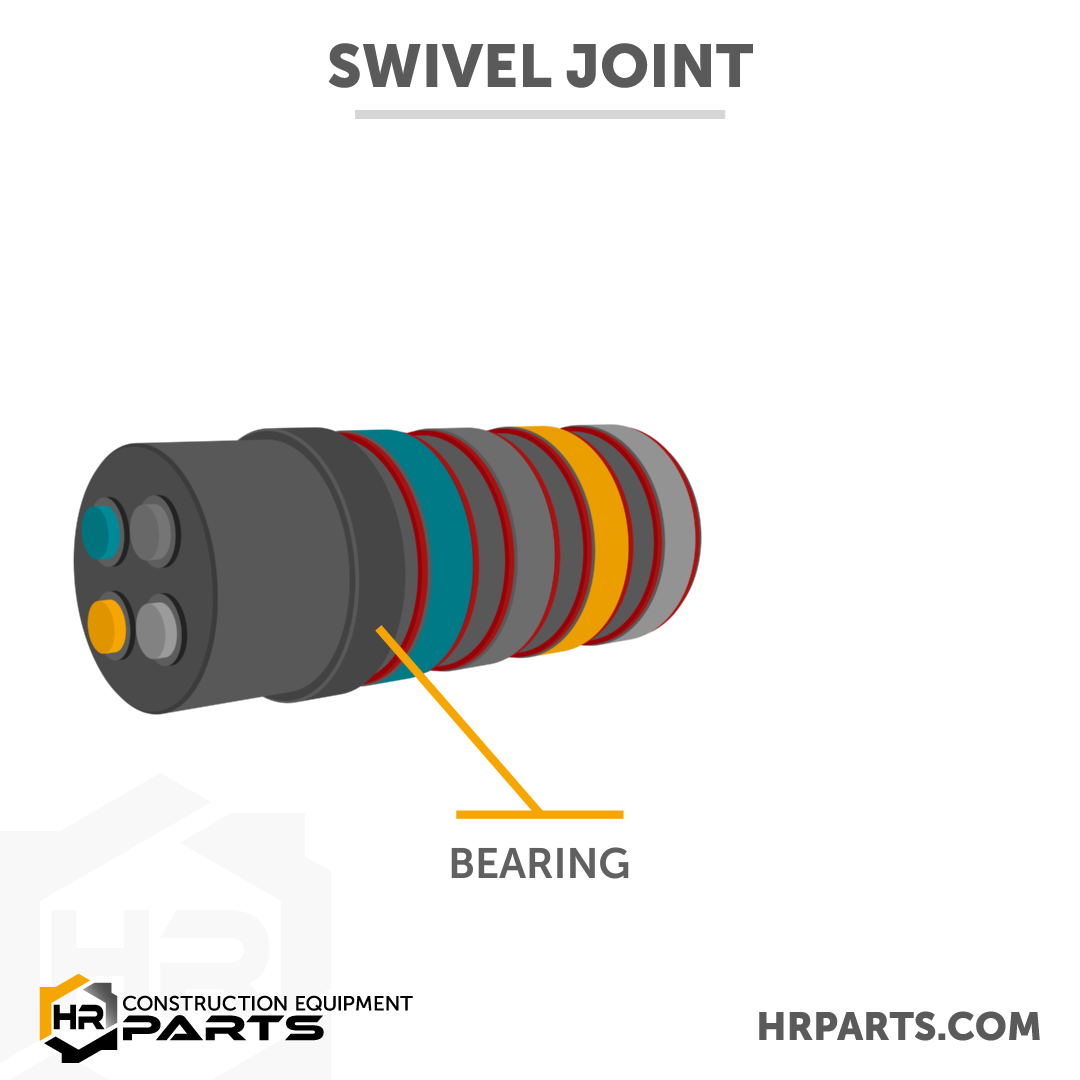

Bearing(s) [View Image]

A bearing (or multiple bearings) are employed between the free-rotating parts of the swivel.

Hopefully, it’s now clear exactly how an excavator swivel works and the important part it plays in an excavator’s unique movements. For many, the excavator swivel only comes to mind when a problem arises, and if that’s the case for you, our Parts Specialists are here to help. As a leader in salvaging excavators and with a reputation for our commitment to providing the best in new, rebuilt, and used parts, we take pride in getting our customers back to work, fast and reliably. Just give us a call.

Swivel Joint / Rotary Distributer Diagram and Photo Gallery